|

Main Page >

About company

> History History1974 Beginning of construction of Pridonskoy Chemical Plant.

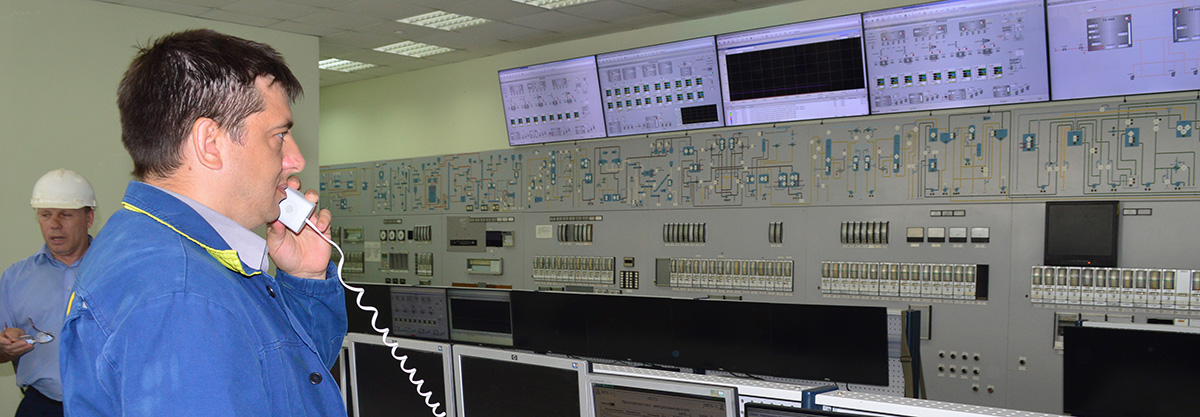

1979 Putting into operation the first phase of the plant: Weak Nitric Acid Plants and Ammonium Nitrate Plant. 1981 Receiving the first product from the first high capacity Ammonia Plant. 1983 Startup of the first plant, producing compound nitrogen-phosphorus-potassium fertilizers — azophoska (NPK Production Plant). 1984 Startup of the second Nitric Acid Plant. Putting into operation the second NPK Production Plant. 1988 Completion of construction and putting into operation of the second Ammonia Production Plant. The first product was received from Liquid Calcium Ammonium Nitrate Plant. While starting the plants, the environmental conservation objects are being constructed and put into operation. 1992 Open Joint Stock Company MINUDOBRENIYA (OAO MINUDOBRENIYA) is registered. 2003 Undergoing of the certification procedures of compliance of quality management system to GOST 9001-2001 requirements. 2004 Issuance of International Certificate of Quality Management System Compliance with the requirements of Standard ISO 9001:2000 by international certifying authority SGS (Switzerland). 2005 The partnership agreement between the Norwegian company YARA International and shareholders of JSC MINUDOBRENIYA was achieved. It was aimed at the implementation of new technologies of the European level with the purpose of increasing the volume of manufactured goods, of production of new grades of fertilizers, increasing their quality. 2005 Connection to ammonia pipeline «Tolyatti-Odessa». 2005 The products liquid technical ammonia, ammonium nitrate, nitroammophoska (azophoska) of grades 1:1:1 and 2:1:1 are awarded with gold sign «All-Russian grade (III millennium). Sign of Quality of XXI century». 2006 Ammonia Plant No 1 reaches the level of production of 10 million tons of liquid ammonia since the moment of its startup. 2006 Record-breaking volume of nitroammophoska (azophoska) output for the whole history of the enterprise. 2006 Beginning of the commercial production of high nitrogen grades of NPK. 2006 Quality Management System of the enterprise passed the recertification audit of the state Scientific Research Institute of Certification to conform to the requirements of GOST R ISO 9001-2001 (ISO 9001:2000). 2007 The year is marked by the number of investment projects aimed at the upgrade of the equipment. The installations of dolomite, magnesite, ammonium sulfate supply, ammonia cooling unit and air conditioning units in NPK Production Plants are constructed and put into operation, the revamp of primary reforming furnace and conversion gas treatment unit in Ammonia Production Plant is completed. 2008 New warehouse of final products for storage of compound fertilizers. Total capacity of the warehouse is 60 thousand tons. 2008 Award with gold medal for production of high quality and environmental safe fertilizers at All-Russian exhibition «Golden Autumn». 2009 Implementation of automatic process control system in AK-72 Plant (production of nitric acid for internal consumption). 2009 Commissioning and putting into operation the Process Calcium Carbonate Drying Installation with a capacity of 200 thousand tons of calcium carbonate per year. 2009 Implementation of the unit of ammonium nitrate packing into big-bags in AC-72 Plant. 2009 Successful passing through recertification audit of quality management system in GOST R and SGS system for compliance with the requirements of standards GOST R ISO 9001:2008 and ISO 9001:2008. 2009 First achievement of ammonium nitrate output of 520 thousand tons per year that is the highest result among RF enterprises using the plants on AC-72 base. 2010 Registration of new grades of NPK-fertilizers — nitroammophoska (azophoska) of nitric-acid attack. Range of products is extended up to 26 grades of NPK. Here are high nitrogen grades and high potassium grades. 2010 Implementation of automatic process control system in Ammonium Nitrate Plant. 2011 Certification of the integrated management system for compliance with the requirements of international standards ISO 9001:2008 and ISO 14001:2004 by international certification authority TUV THURINGEN e.V. 2018 Certification of the integrated management system for compliance with the requirements of international standards ISO 9001:2015 and ISO 14001:2015 by international certification authority TUV THURINGEN e.V. 2020 Technical revamp of AK-72 Plant (Weak Nitric Acid Production Plant). 2021 Putting into operation new Air Separation Unit (ASU) in Liquid Mineral Fertilizers Production Plant. 2021 — 2022 Technical revamp of AC-72 Plant (Ammonium Nitrate Plant). 2022 Upgrading the equipment in Ammonia Production Plant No 1 within implementation program for increasing the products output and reducing energy consumption. |